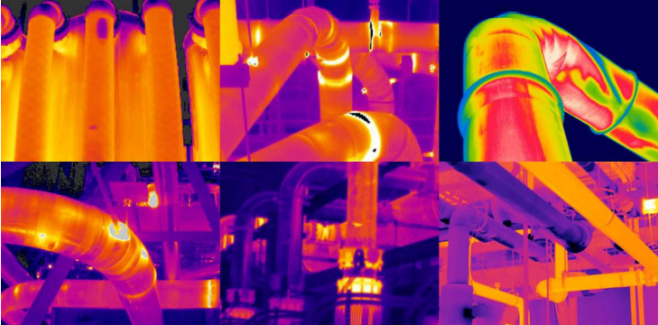

Application of infrared thermal imagingin Petro Chemical industry

Petrochemical industry involves many inflammables and explosives; therefore, special attention shall be paid to the work safety. As a long-distance non-contact temperature measurement technology, infrared thermal imaging is widely used in equipment walk-around inspection and on-line monitoring of petrochemical industry, which may provide a reliable technical guarantee for intelligent equipment health and safety management.

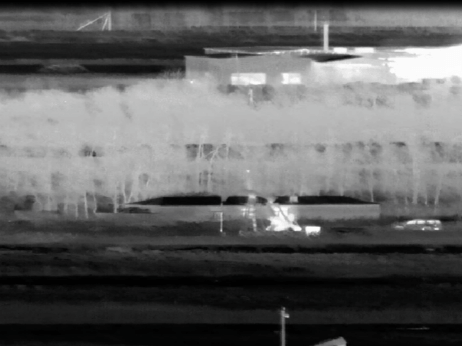

Oilfield exploitation monitoring

Oil fields play an important role in both national and local economy. Oil exploitation areas are widely distributed in remote areas in large scales. Considering that pumping wells have been seriously damaged and crude oil has been stolen, infrared thermal imaging may realize all-weather, all-time and multi-dimensional investigation and monitoring under seamless coverage, which may provide a reliable guarantee for oil exploitation.

Recommended product

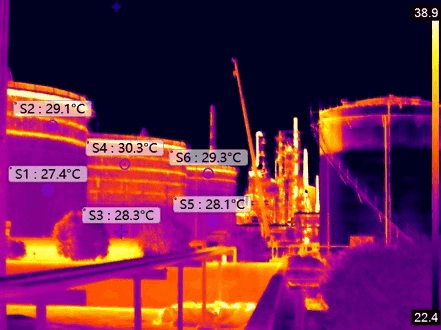

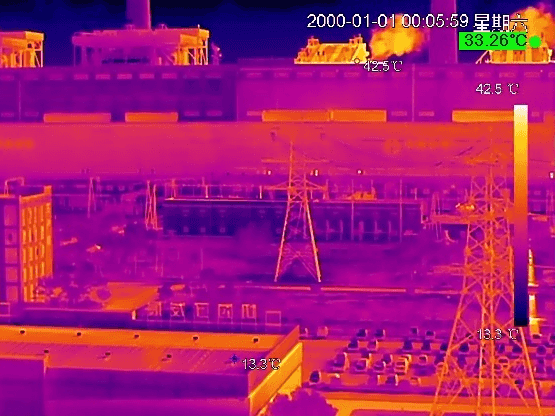

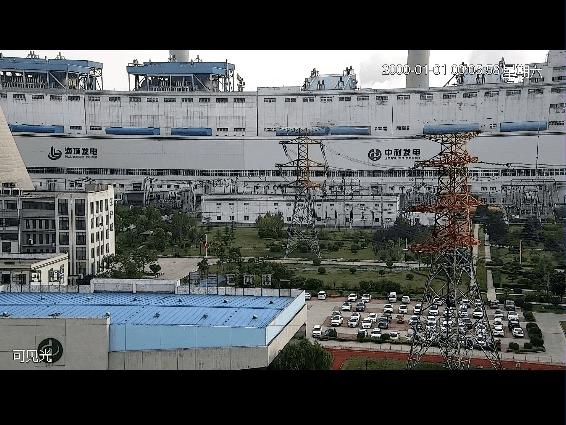

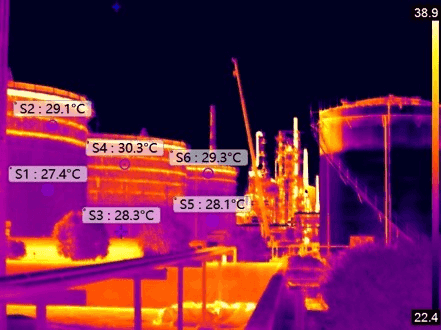

Chemical industry park

There is high frequency of accidents in Chemical industry parks which are full of plant houses and dangerous chemicals in China. Therefore, high-definition thermographic cameras have been installed at high altitudes for comprehensive and all-round monitoring to ensure the work safety, and potential hazards may be pinpointed in a timely manner by monitoring over temperatures in the parks.

Recommended product

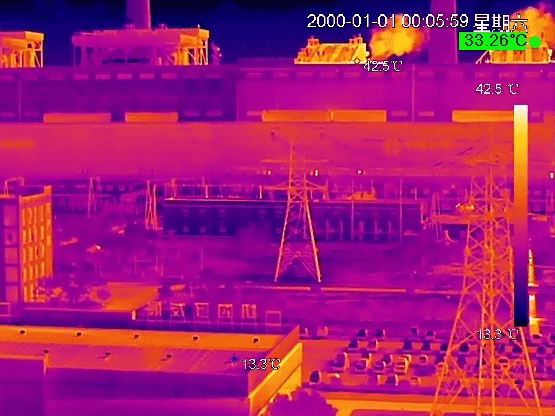

Tank level monitoring

Tank level gauge may indicate false liquid levels while infrared thermal imaging may directly capture the liquid level on the outer surface to help the operation and maintenance personnel locate faults in a timely manner, or conduct in-depth detection over the tank body without clear storage capacity to avoid potential hazards.

Recommended product

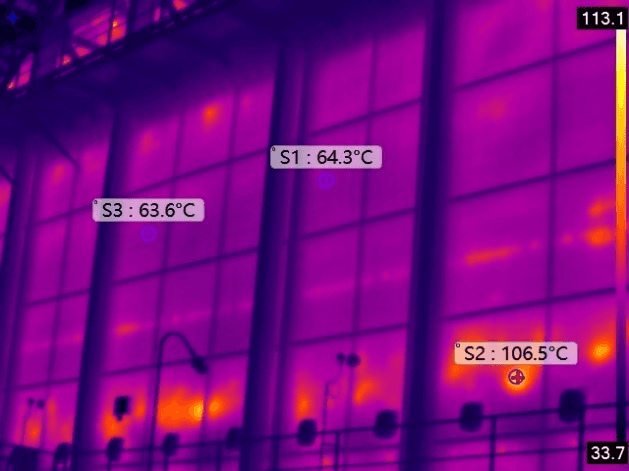

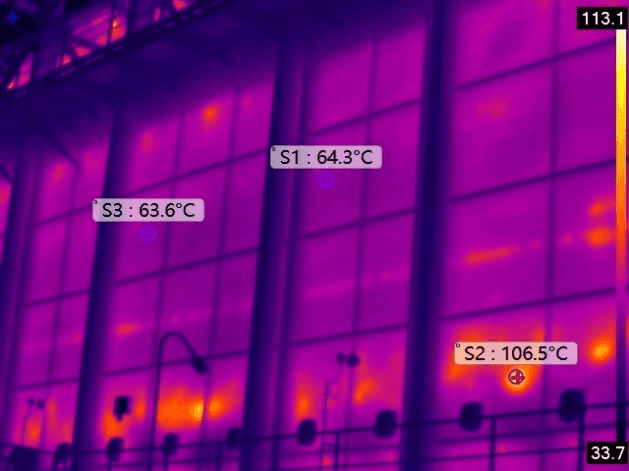

Energy saving transformation and temperature measurement of the furnace body

Refinery heating furnaces with low thermal efficiency and high energy consumption have great energy-saving potential. Infrared thermal imaging equipment may be used for surface temperature measurement with report generated automatically. Instead of traditional point temperature measurement and manual input calculation, the equipment may help front-line engineers quickly obtain the transformation effect and improve work efficiency.

Related to the case