Application of Infrared Thermal Imaging in Electric Power Industry

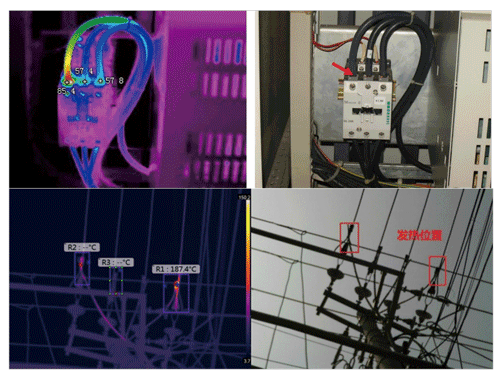

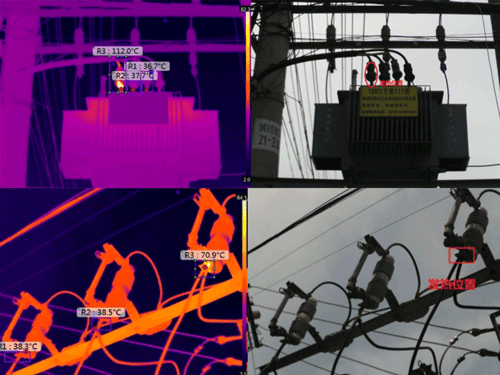

During the operation of power systems such as power generation, transmission, transformation and distribution, different degrees of thermal defects of various equipment and lines may occur due to complex operation environment, long operation and other factors. Non-contact infrared thermal imaging is the optimum choice for detecting thermal defects of equipment. Through temperature detection, image analysis, intelligent diagnosis and other technologies, operators may confirm potential safety hazards and locate defects timely at a safe distance, so as to reduce the occurrence of accidents and ensure the safe and economic operation of the power grid.

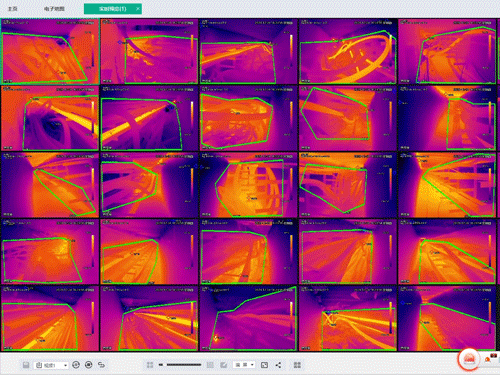

Panoramic Monitoring of Wind Farms

Most wind power stations in case of potential safety hazards, which are not discovered and eliminated in a timely manner during operation of the generator units, the generator units may be burnt or even collapse.The panoramic monitoring solution provided by Guide in the field of wind power may realize "Panoramic monitoring with one camera" within 5km, presenting high-definition image details, and monitoring thermal state distribution of equipment in real-time.

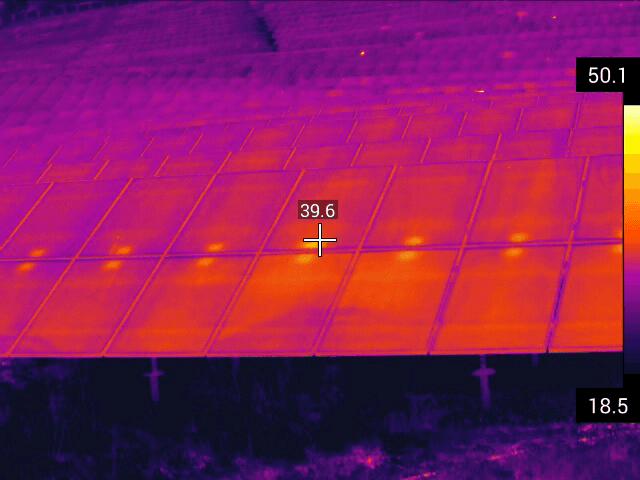

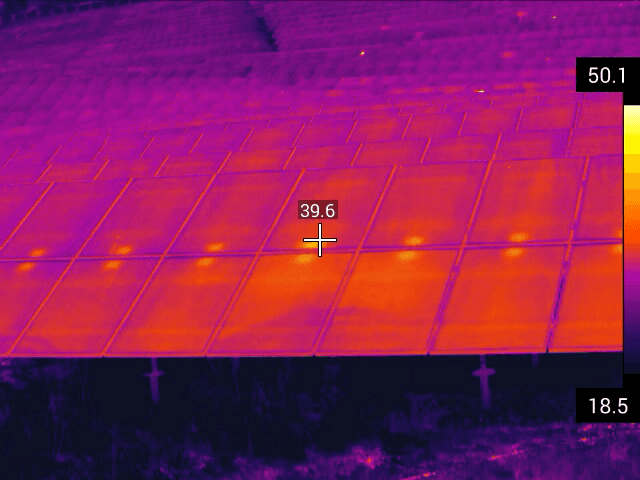

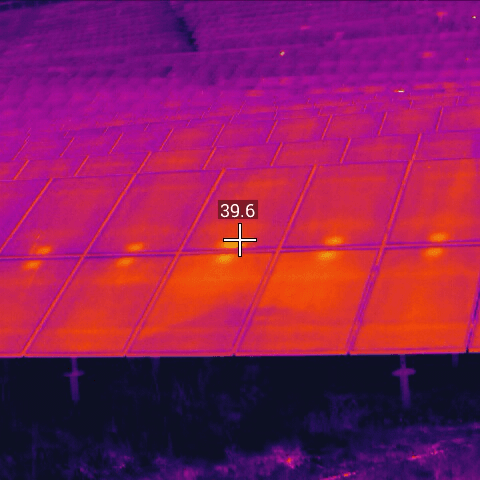

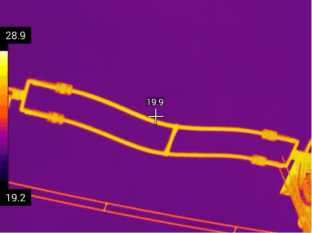

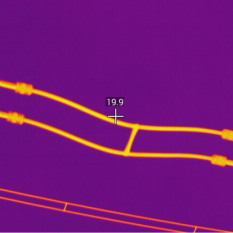

Photovoltaic Panel Detection

Photovoltaic power generation mainly relies on crystalline silicon solar panels to convert solar energy into electric energy through photoelectric conversion effect. In the open outdoor, hidden defects of the silicon wafer of photovoltaic panel may occur due to the variable natural environment such as thermal stress, sand and dust and storms. The high-performance intelligent thermographic cameras may help enterprises detect the defects of solar panels, such as cracks, broken gates and black wafers in a timely manner.

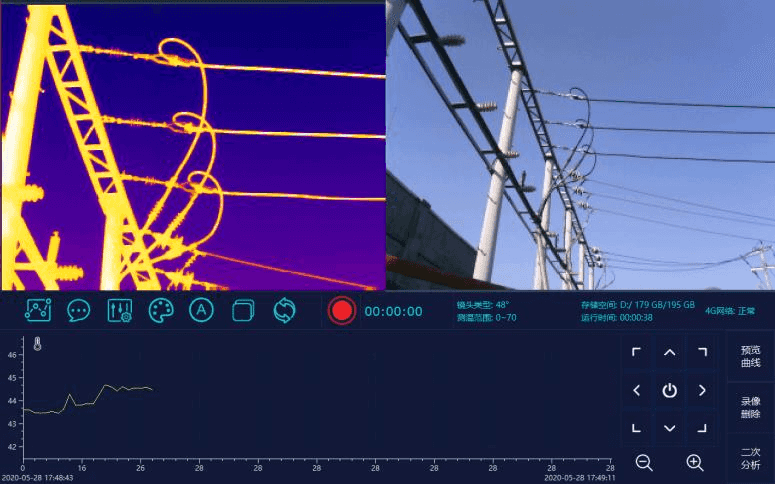

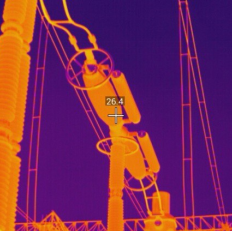

Real-time thermal imaging monitoring of transmission line insulators

Transmission line insulators are used not only to insulate electrical equipment or conductors, but also for fixation and suspension; therefore, the insulation performance of insulators will be reduced due to the long-term exposure to complex and harsh environment including strong electric field, high temperature sunlight and pollutants. The infrared thermal imaging monitoring solution for transmission line insulators provided by Guide may realize the full life cycle monitoring over UHV transmission line insulators and provide analysis data support for the whole process of subsequent insulator deterioration.

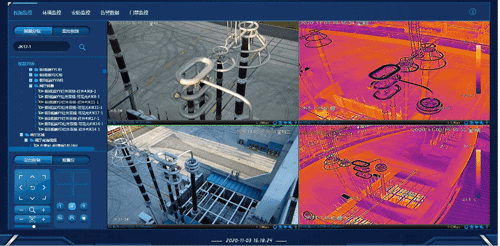

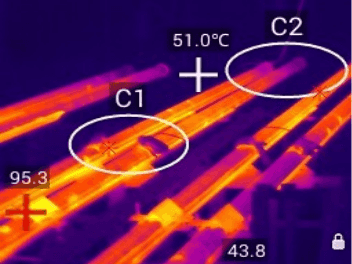

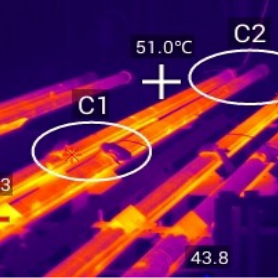

Real-time infrared thermal imaging monitoring of cable trenches

The cable trench structure is complex with multiple high-voltage cables routed in parallel. In case of loose cable joint and excessive contact resistance, long-term operation will cause overheating of the cable joint with the insulating layer burned through, and finally lead to fire in the cable trench. Therefore, the significance of the safety of cable trenches cannot be ignored. The infrared thermal imaging solution for cable trenches provided by Guide may accurately realize the on-line temperature monitoring over the target objects, and has the functions of automatic warning, remote control, manual temperature measurement, trend analysis, statement management, etc.

Related to the case