Application of Infrared Thermal Imaging in Iron and Steel Metallurgy

In the process of iron and steel metallurgical production, a variety of advanced technical means such as sensing technology, soft measurement, machine vision and data analysis may help enterprises achieve a safe, accurate and intelligent production level. As a long-distance non-contact temperature measurement technology, infrared thermal imaging is widely used in Iron and steel metallurgy manufacturing process. It is the key to detect, control and optimize the process in Iron and steel metallurgy manufacturing process.

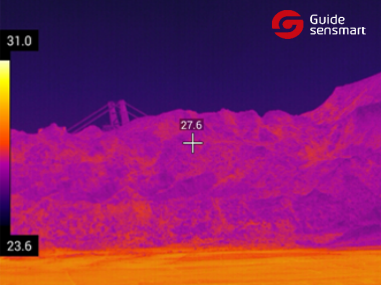

Raw material fire prevention and monitoring

Coal is stacked in the coal yard as a raw material in the process of iron and steel metallurgy. Due to the long-term stacking, the temperature of the coal rises continuously, which is easy to cause spontaneous combustion or smoldering of the coal stockpiles resulting in great losses of the enterprise. Infrared thermal imaging may monitor and measure the internal temperature of coal stockpiles in a long distance and large range, so that operators may timely understand the heating condition of coal stockpiles, and take measures as soon as possible to avoid spontaneous combustion of coal stockpiles.

Recommended product

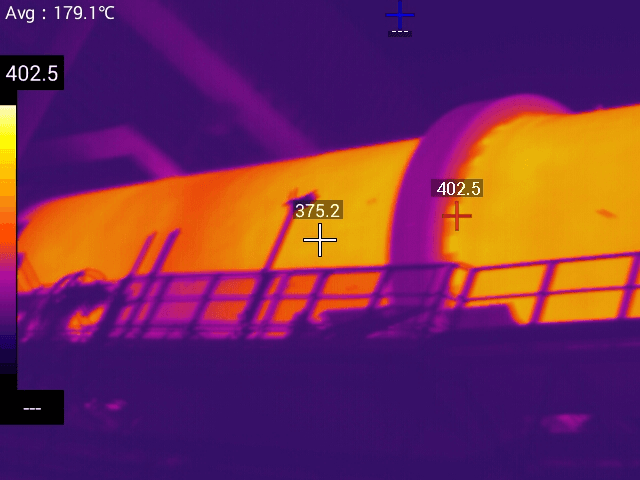

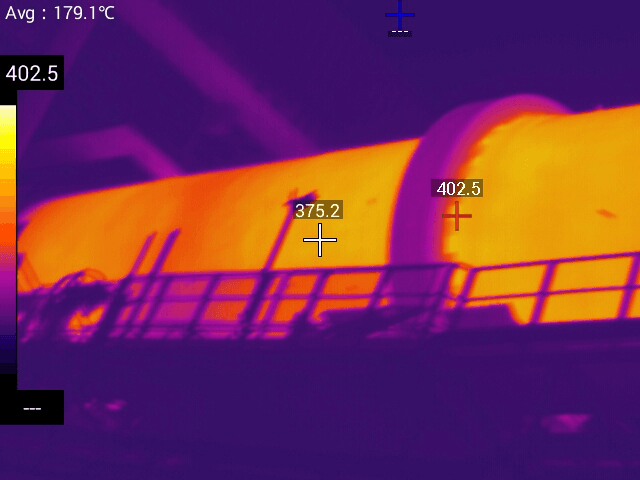

Rotary kiln monitoring

The melting state of combustion is easy to cause coking, which may pull rings and accumulate at the rear affecting slagging;then, the boiler needs to be shut down for coke removal and the operation reliability of the equipment will be affected. Infrared thermal imaging can monitor the temperature during the production and operation of the rotary kiln, find the high-temperature area as soon as possible, help to arrange the maintenance plan in advance, prevent equipment failure and potential safety hazards, and avoid shutdown caused by the sudden falling off of refractory materials.

Recommended product

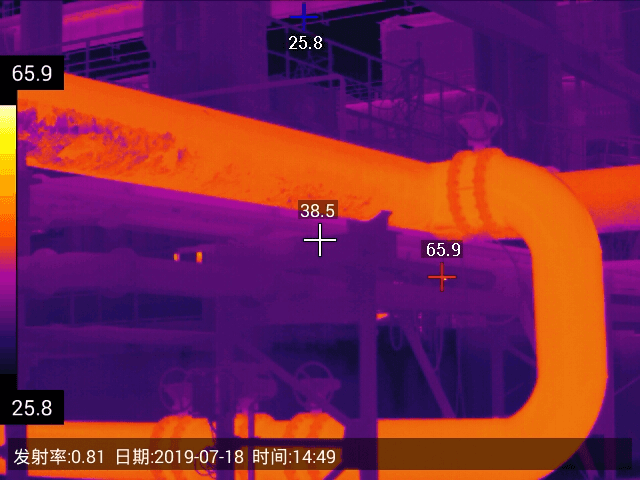

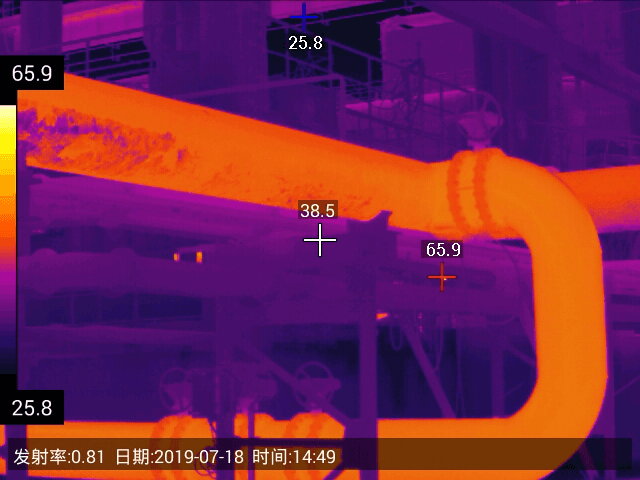

Steam pipeline leakage monitoring

The thermal insulation materials of common thermal pipelines in iron and steel smelting enterprises are prone to be ruptured or damaged under the influence of steam temperature and high pressure, resulting in leakage and energy loss as well as major potential safety hazards during the operation of thermal pipelines. The thermographic camera may quickly measure the thermal information of the target surface and visualize it in the form of image, quickly read the temperature and locate the fault, so as to help front-line engineers quickly troubleshoot the pipeline network.

Recommended product

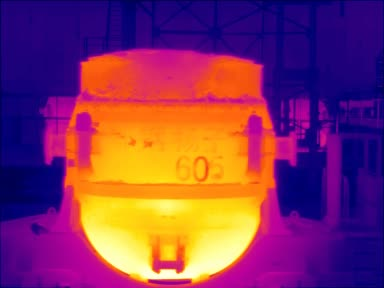

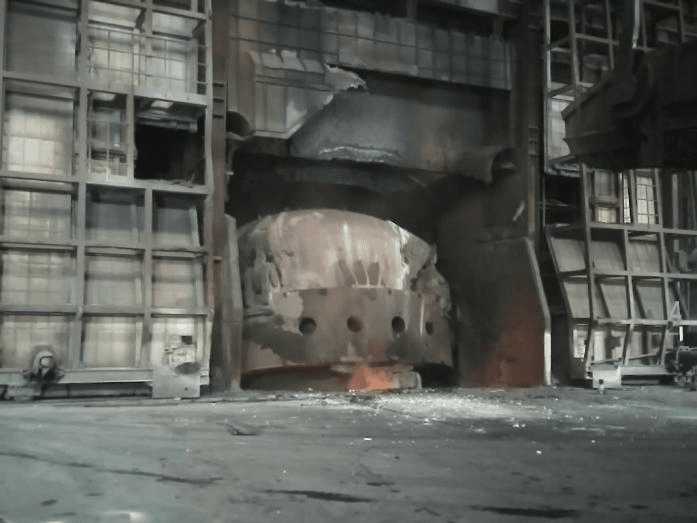

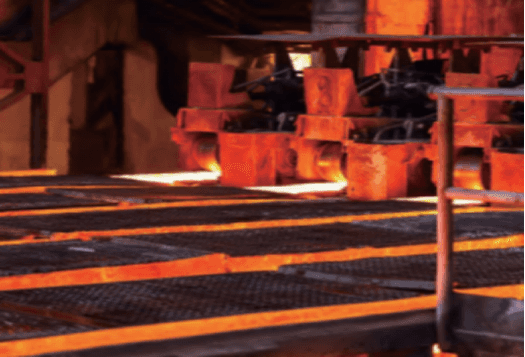

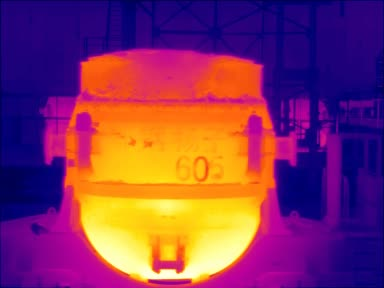

Defect detection of steel ladles and torpedo ladles

In the process of iron and steel smelting, there would be potential hazards such as invisible wall thinning and notch of steel ladles, torpedo ladles and iron slag ladles for a long-time running, which may cause major industrial accidents. Therefore, using the on-line thermographic camera to monitor the surface temperature of the ladles throughout the day, determine the temperature and differences of the ladles, and monitor the safe operation of the ladles. Adopt uniform standard for monitoring can help operators understand the conditions of the ladles more simply and directly.

Recommended product

Related to the case